The role of solvents in chemical recycling

Pyrolysis, gasification, and solvent technologies are revolutionizing how we turn waste and biomass into valuable products and energy. We have already explored the heat-driven magic of pyrolysis and gasification, now it is time to meet the quiet catalyst behind the scenes: solvents.

From breaking down plastics to refining bio-oils, solvents are essential to chemical recycling and the cleanup of pyrolysis and gasification outputs. They are not just supporting players, they are unlocking cleaner, more efficient pathways to a circular economy.

Articles related to pyrolysis and gasification:

Solvents: The silent workhorses of material processing

Solvents play a critical role in upgrading and refining the outputs of pyrolysis and gasification. They’re used to separate and purify bio-oil, making it more suitable for downstream applications. In biomass pyrolysis, solvents can selectively extract tar components, improving product quality and reducing unwanted residues. Beyond cleanup, solvents are also central to producing valuable chemicals—like oxygenated solvents such as alcohols, glycols, and ethers—that serve as building blocks for fuels, plastics, and pharmaceuticals.

What are solvents and how do they work?

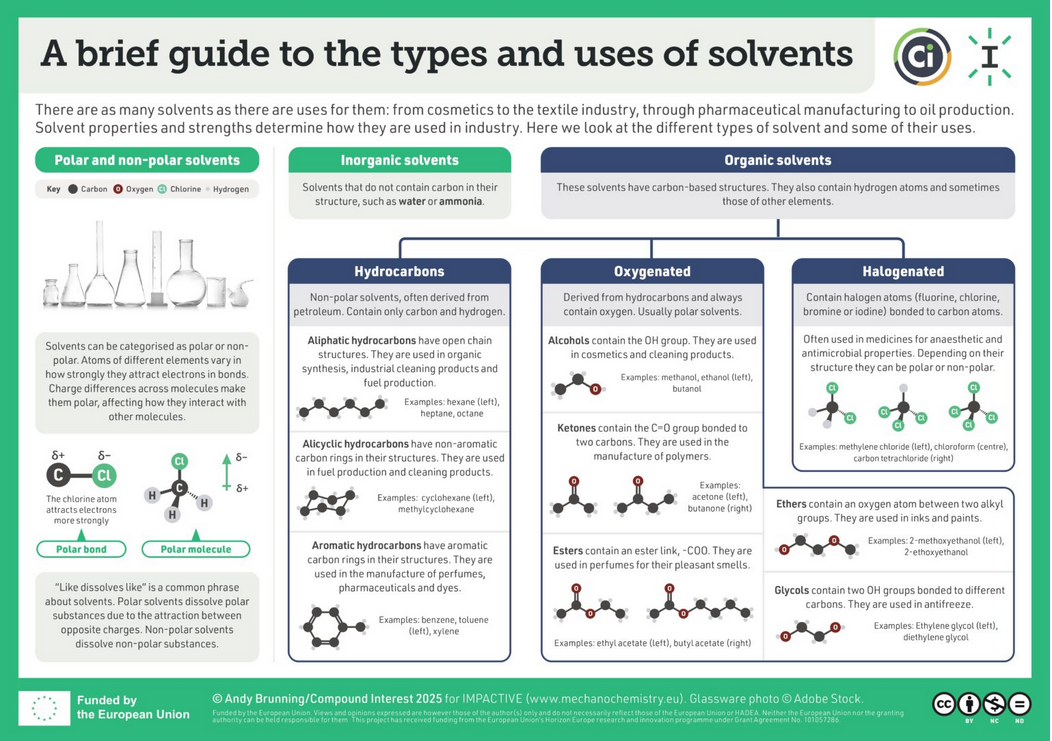

A solvent is a substance that dissolves another material, known as the solute, to form a solution. In most cases, the solvent is the component present in the larger amount. Water is the most familiar example, but solvents come in many forms,organic, inorganic, polar, non-polar, each with unique properties and applications. Have a look at the brief guide below.

Solvents work by surrounding solute molecules and disrupting the forces that hold them together. This interaction breaks the solute’s internal bonds and disperses its particles evenly throughout the solvent, creating a homogeneous mixture. The effectiveness of a solvent depends on its chemical nature and the type of solute, hence the classic rule: “like dissolves like.”

Available technology: Solvent-based recycling for polymers

Solvent-based recycling, also known as dissolution-based recycling, is a chemical method for recovering high-quality plastics from complex or contaminated waste. Instead of breaking down polymers into monomers (as in depolymerization), this process dissolves plastic waste in a solvent to separate and purify different polymer types.

How It Works:

The solvent selectively dissolves target polymers while leaving others intact.

Impurities, such as colorants, odors, additives, and contaminants, are removed during the process.

The purified polymer is then precipitated and recovered as granulates with properties comparable to virgin plastic.

Why It Matters:

Maintains the polymer’s chain structure, preserving material integrity.

Offers a hybrid advantage: chemical precision with mechanical simplicity.

Enables recycling of multi-layer packaging, mixed plastic waste, and contaminated streams that are challenging for traditional methods.

Environmental Benefits of Solvent-Based Recycling

Solvent-based recycling, particularly dissolution processes, stands out as one of the more environmentally favorable chemical recycling methods, especially when compared to high-impact technologies like pyrolysis and gasification. Studies show that gasification tends to have the highest gross environmental impacts per unit of input, followed closely by pyrolysis. While depolymerization and dissolution share some overlap with pyrolysis in terms of impact, they generally perform better, especially when optimized for specific waste streams.

One of the key advantages of solvent-based recycling is its ability to recover high-purity polymers with relatively low energy input, provided the plastic waste is properly sorted beforehand. This requirement for prior sorting, by polymer type, can be a logistical and economic challenge, but from an environmental perspective, it pays off. The cleaner input allows dissolution and depolymerization to operate more efficiently and with fewer emissions, making them strong complements to mechanical recycling.

Although these processes are limited in the types of waste they can treat, their environmental performance is consistently superior to incineration. In scenarios where solvent-based methods are combined with pyrolysis or gasification, the overall impact can vary widely depending on the configuration. Still, dissolution and depolymerization remain among the most promising pathways for reducing the footprint of plastic waste treatment.

Combining Dissolution and Pyrolysis: Enhancing Bio-Oil Quality

Fast pyrolysis of biomass produces a complex, unstable mixture known as pyrolysis oil—a multi-phase colloidal system rich in diverse compounds such as alcohols, aldehydes, ketones, esters, acids, aromatics, furans, phenols, sugars, guaiacols, and water. While this bio-oil holds promise as a renewable energy source, its direct application is limited by several undesirable properties. Compared to conventional mineral oil, pyrolysis oil is more acidic, has higher viscosity, lower thermal stability, and a reduced heating value.

To unlock its full potential, post-treatment is essential, and this is where solvent-based technologies come into play. One particularly effective method, explored in studies, is solvent–anti-solvent extraction, which selectively isolates problematic components like water and sugars from the pyrolysis oil. By removing these fractions, the process improves the oil’s physical and chemical properties, making it more stable, less corrosive, and better suited for energy or chemical applications.

This combination of dissolution and pyrolysis represents a powerful hybrid approach: pyrolysis breaks down biomass into valuable intermediates, while solvent-based extraction refines and upgrades those intermediates for practical use. Together, they offer a pathway toward cleaner, more efficient bio-based fuels and chemicals.

Although solvent-based recycling processes are generally less developed than traditional methods like mechanical recycling, they are gaining significant momentum. One of their key advantages lies in the fact that polymer bonds remain intact during processing. This means the molecular structure of the recovered polymer is virtually identical to the original material, preserving its performance characteristics. At the same time, solvents effectively remove additives, dyes, and other contaminants, resulting in a virgin-like polymer that can re-enter manufacturing streams without compromise. As industries seek cleaner, more precise recycling solutions, this ability to restore high-quality material without degrading its structure is driving renewed interest and innovation in solvent-based technologies.